At ITFAB, innovation is at the core of our philosophy and operational practice, and is deeply integrated into our corporate DNA.

Through the application of 3D printing technologies and the use of 100% recycled raw materials, we are in a constant quest to expand and transform traditional manufacturing paradigms. This innovative approach is not only limited to the design and production of high-fidelity, dimensionally accurate custom products, but also includes the research and development of new geometries and finishes that only 3D printing can achieve.

By using recycled materials, ITFAB not only optimizes production efficiency and final product customization, but also positions itself as a leader in the transition to greener and more sustainable digital manufacturing practices.

100% recycled raw materials

At ITFAB we believe in sustainability as an element that adds value to our products. Therefore, whenever the project allows it, we will work with raw materials with certification and traceability from their origin.

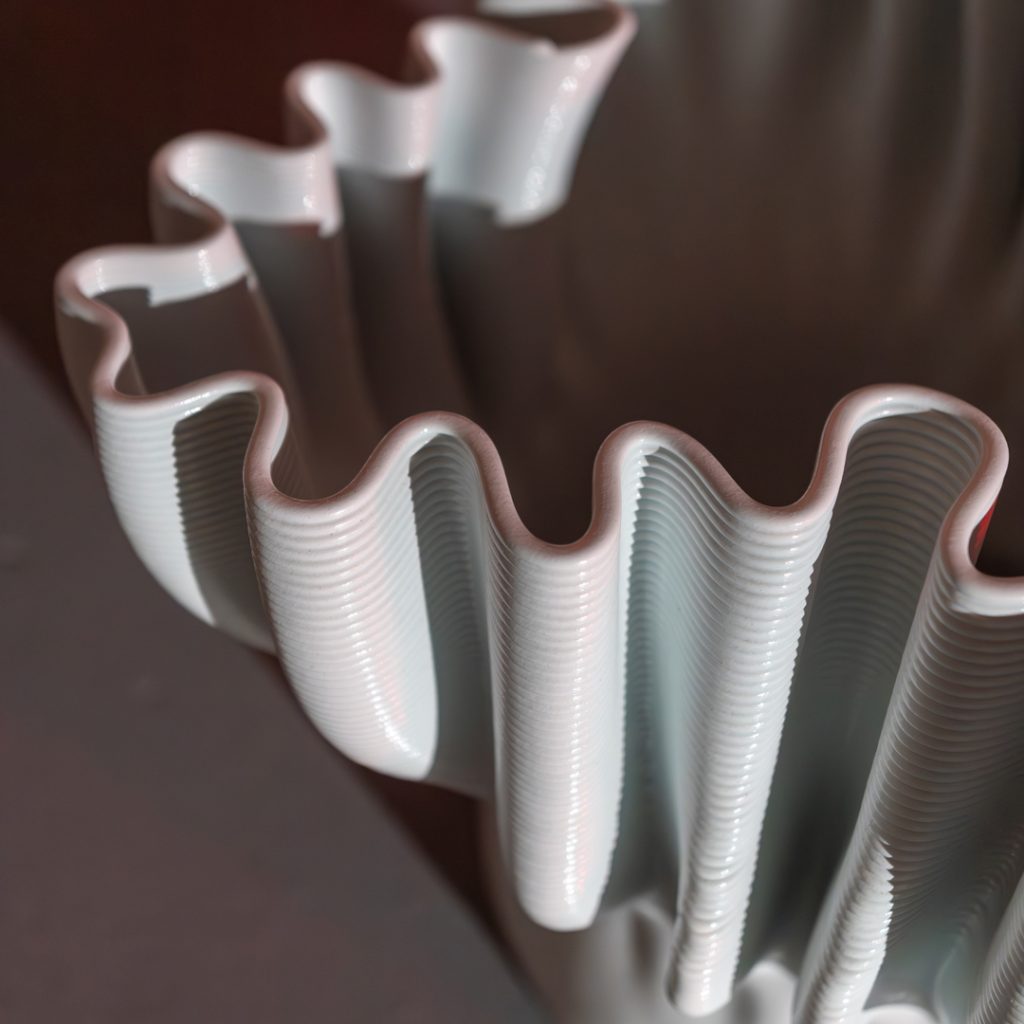

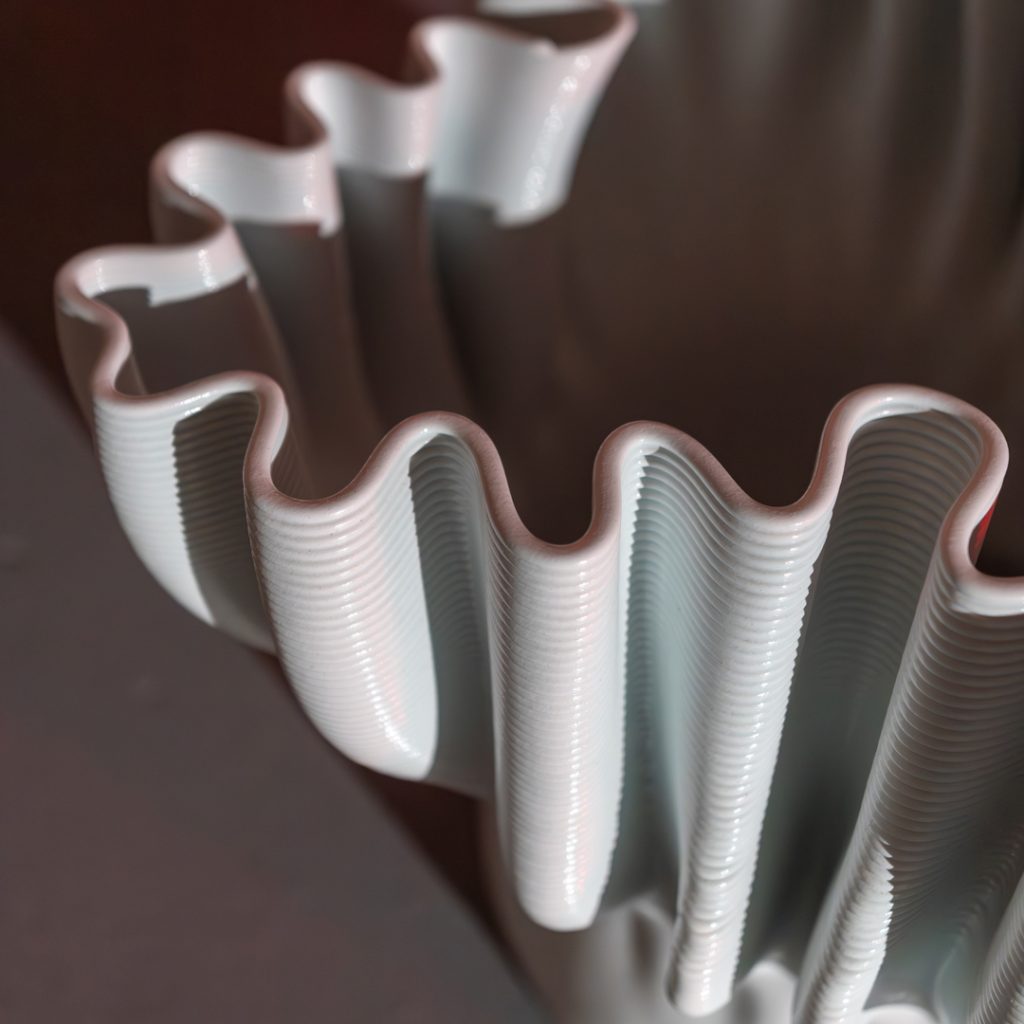

Robotization and kinetic sculpture

We bring the possibility of creating interactive and dynamic works. In addition, 3D printing and automation allow us to explore new forms of artistic expression and merge technology with creativity, expanding the aesthetic and conceptual possibilities in this field.

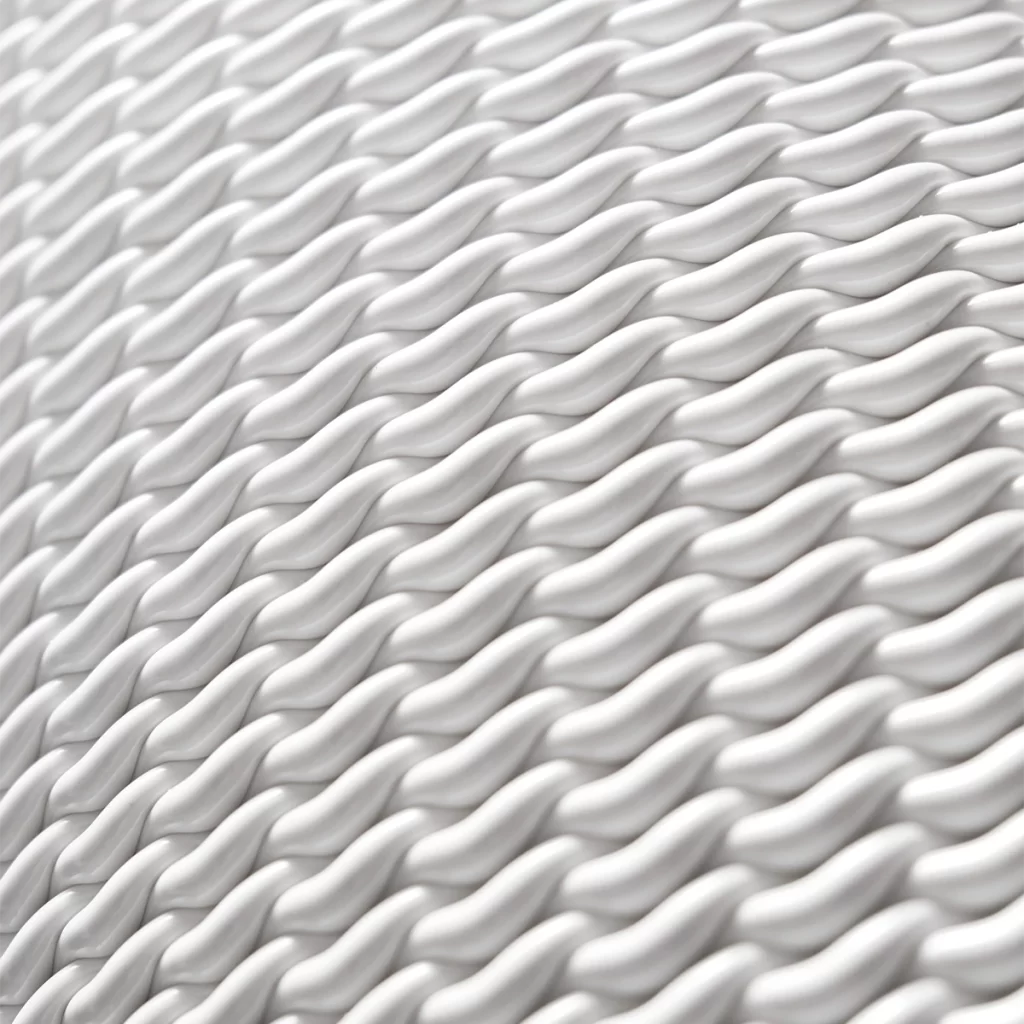

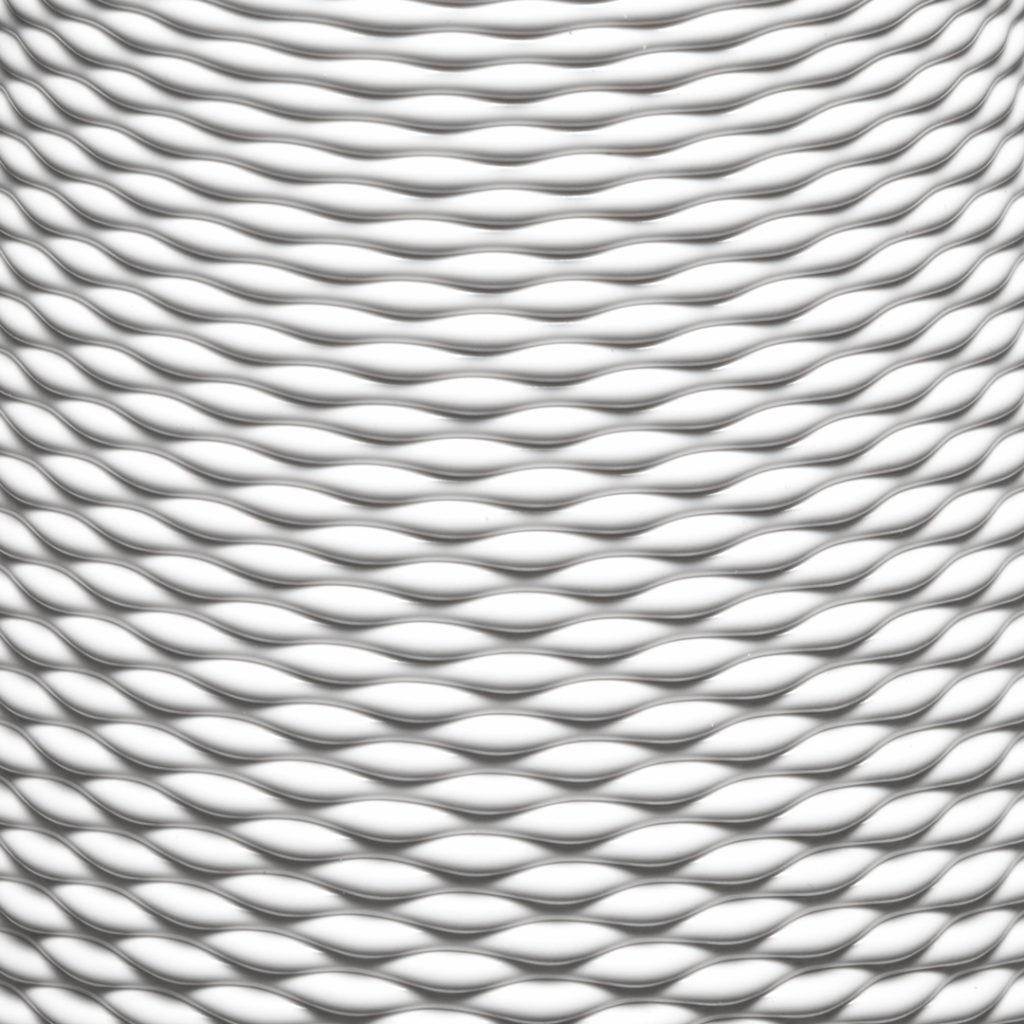

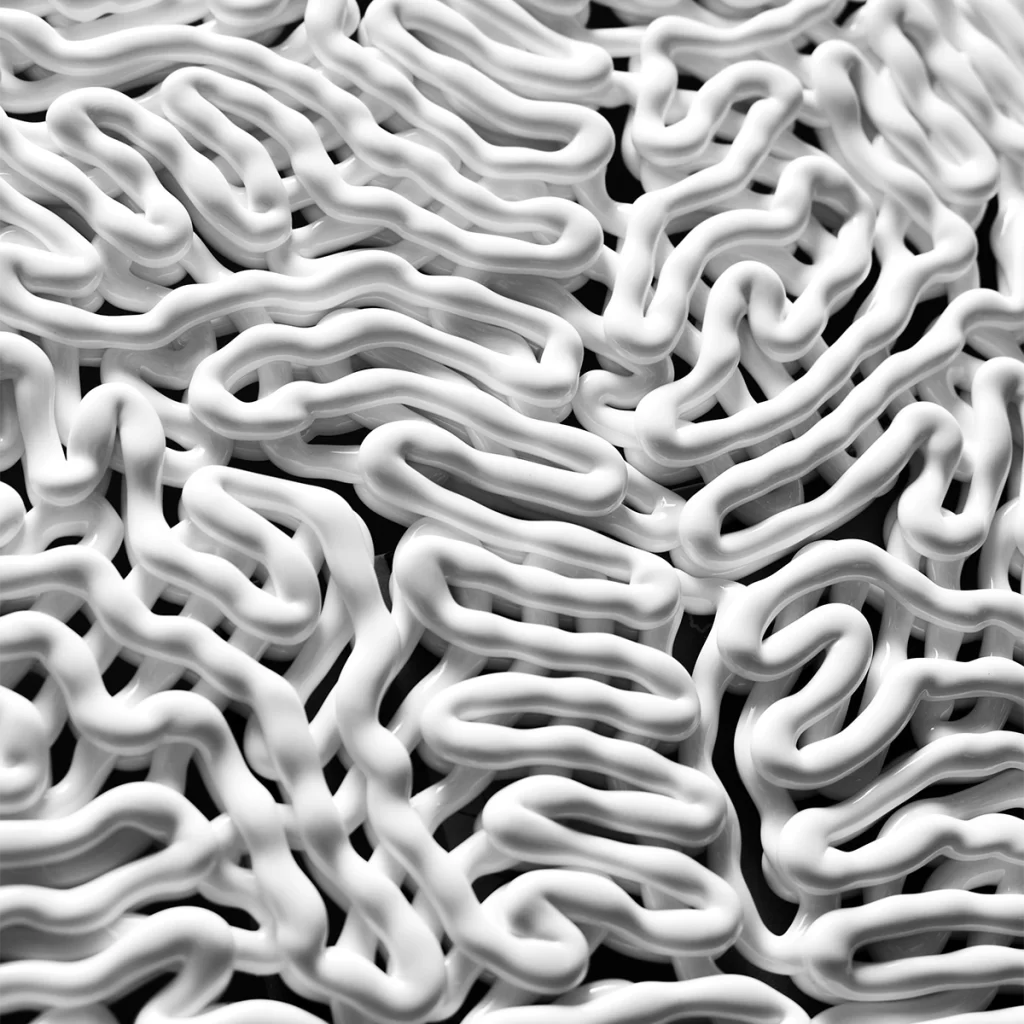

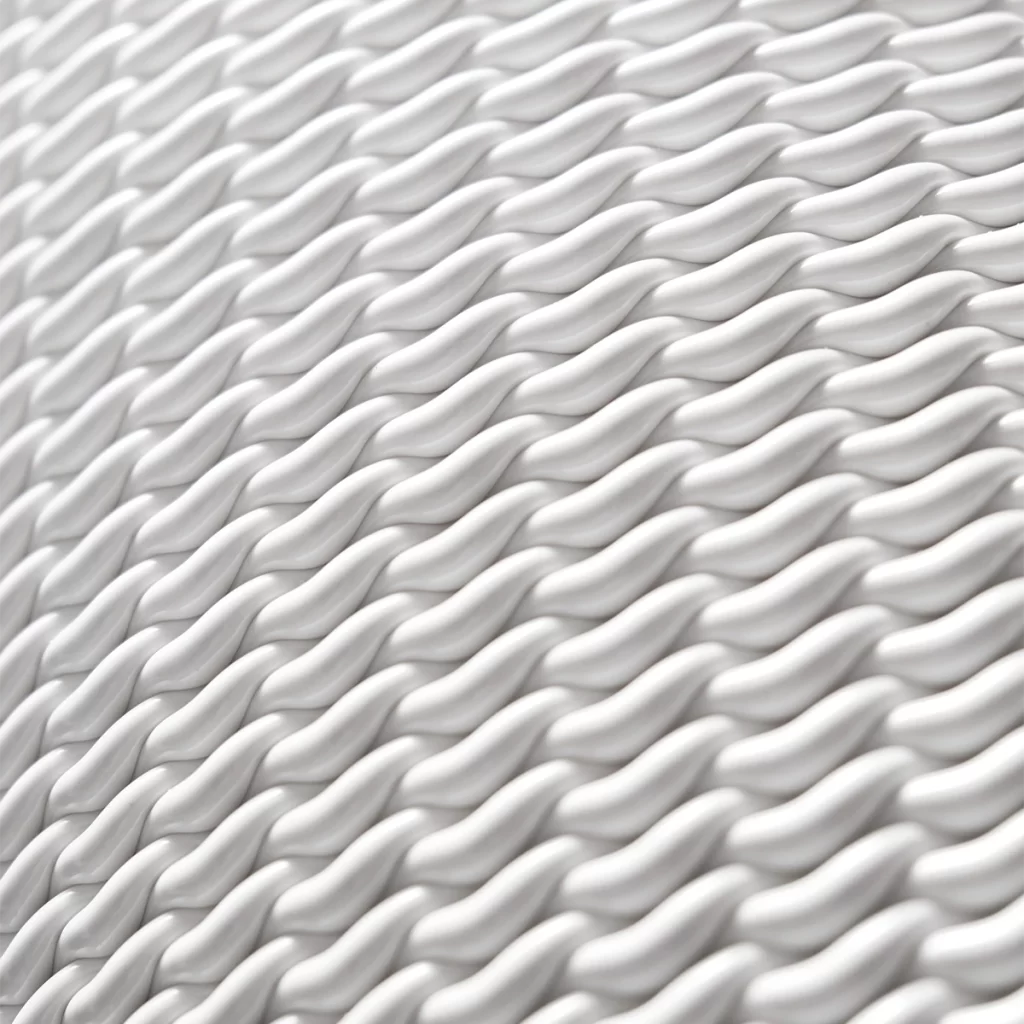

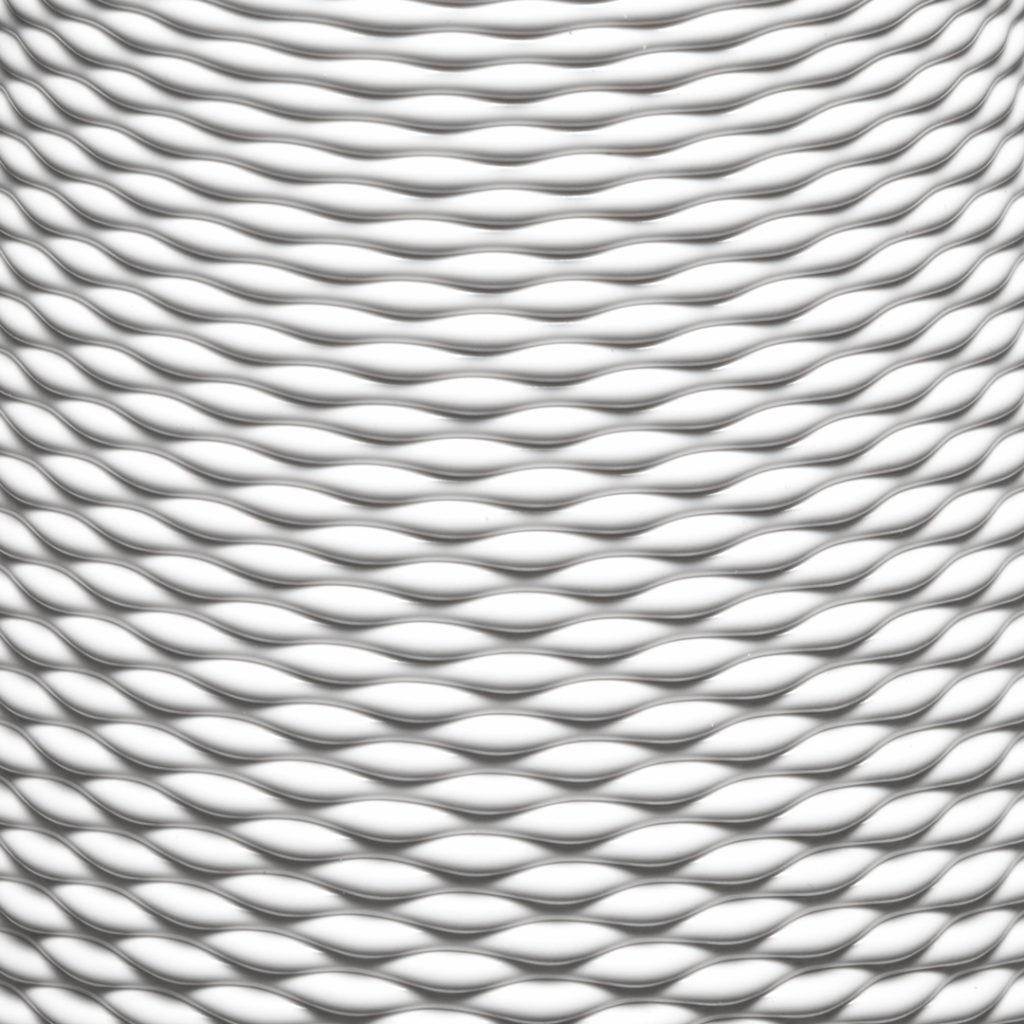

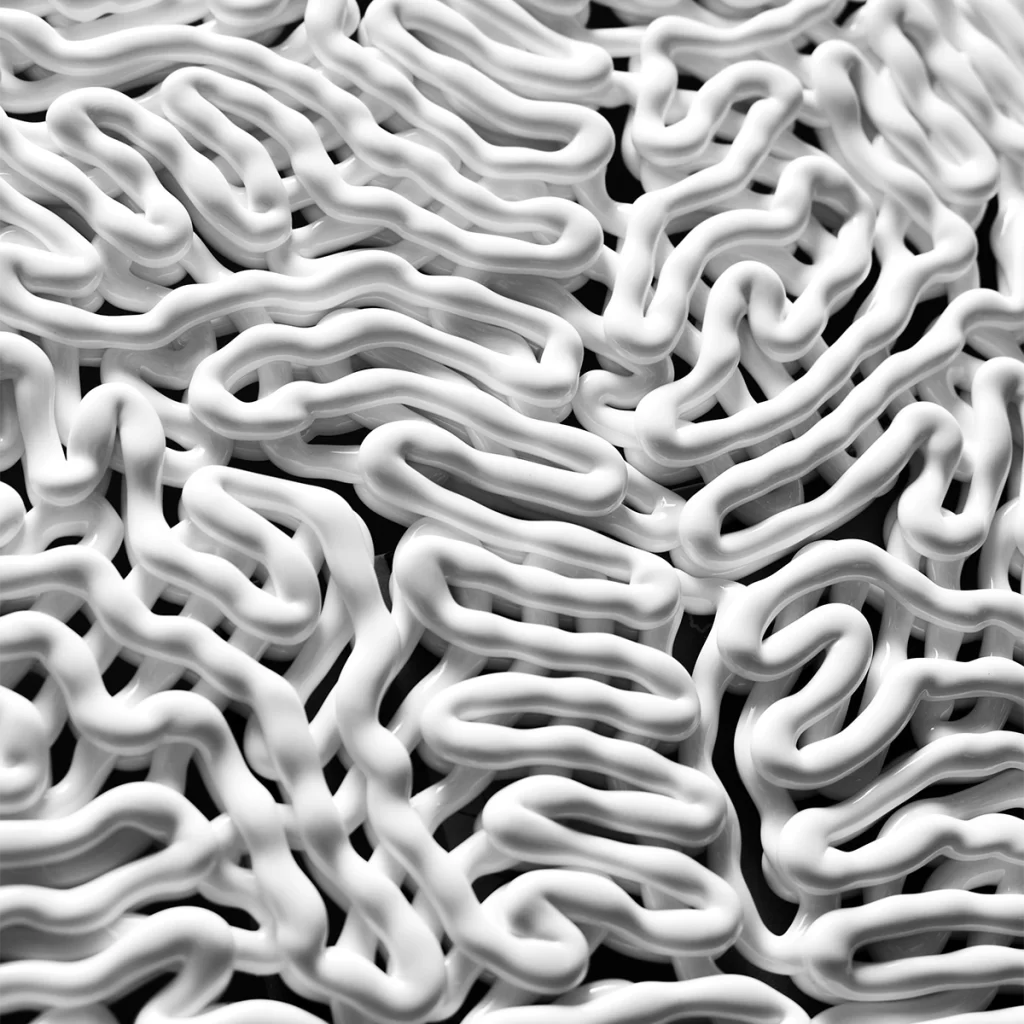

Texture exploration

We provide unprecedented geometric and aesthetic freedom by enabling the creation of complex shapes and designs that would be difficult or impossible to achieve with traditional methods. This technology revolutionizes the way we conceive and materialize art and design, freeing creativity to explore new aesthetic frontiers.